Almost all of the material items we own eventually reach an end of life stage when they are no longer usable.

This is a particular problem in the surf industry, as broken and outdated boards, fins and other accessories become huge pollutants in our natural environment.

Up until now, Starboard has taken action on this by working on making boards that last longer, from materials that are less polluting. But we are now asking ourselves, what can we do with our board’s when eventually they do reach their end of life?

SUPing and Windsurfing is a great way to connect us to nature, and it opens up our eyes and minds to the pollution littering our waterways and shorelines. However, how often do we think about the direct impact that is created from the production of boards and equipment? What happens at the board’s end of life?

Images above from Seatext Boards who successfully work on repairing boards so they can be used again! Repaired board in photos is Starboard iSonic 145. So we know we can repair boards but what happens when the damage is too much to repair?

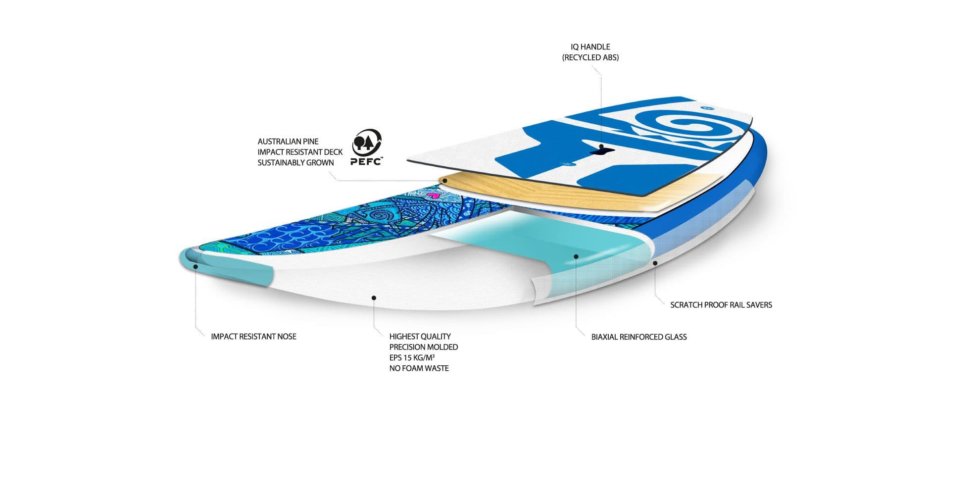

On average a board is made of approximately 7 different types of plastic. These various materials are really tricky to recycle as each material is stuck to another with resins or glues. The end of life of boards however does need to be tackled. After the fixing dings, cuts, scraps etc. boards may come to their very end of life when they’re stuck beyond repair!

2020 Construction of Tikhine Hardboard, Showing Different Materials

2020 Construction of Tikhine Hardboard, Showing Different Materials

What We Are Currently Looking At When It Comes To A Boards End Of Life?

Firstly by seeing which materials are large enough, and ‘uncontaminated’ with resins, we can see how we can easily take these materials away and easily separate them. From here we would reach out to recycling companies that are currently working with such materials. Discussions with these recycling companies will help identify how we can work with them to become a feed source of a waste stream. By becoming part of a waste stream, we would need to work with the recycling centre or company to make sure the recycled material is then used efficiently in another product and not just lying around waiting to be used.

Communication Is Key!

The Starboard Blue team have been in communication with various relevant suppliers and stakeholders. By asking around we have begun to develop a network of interested companies and individuals who are helping in the research process. Furthermore, we have had conversations with The Green Blue, World Sailing, British Marine and using the Composites UK website. All of these conversation are helpful in leading us down a route of understanding. Helping us to plan our next action.

What Is Currently Happening To Boards At The End Of Their Water Based Life?

Sadly, most are still going to landfill. However, there are many ways to upcycle a board, to re-use its materials and help extend their life before reaching landfill. Such recycling projects or upcycling projects include transforming boards and paddles into tables, benches and artwork. Companies such as Sea Monkeys are also able to re-use kites and sails to make awesome bags!

Starboard Upcycle Some Boards and Use Them For Benches Around HQ

How Do We Find A More Sustainable Solution For A Board’s End Of Life?

We need to take action to reduce our impact on the planet which supports us so much within our day to day lives. When designing we need to ensure we are utilising as many recycled or sustainably sourced materials as possible. Removing our reliance on virgin unsustainable resources, without limiting the quality and performance of our products. While developing new boards we need to be designing with the intention of making a board easier to break down when they do reach their end of life. By making the breakdown of boards easier, we can increase the amount of material we can separate, categorise and recycle.

What can you do to help?

Please contact tasmin@star-board.com to share with us what you are doing with your boards, or sails when they come to their end of life. Or any ideas you may have for how we can improve the end of life process for our products.

More info at https://blue.star-board.com