Starlite

Construction Technology

Crisp and Sharp

Windsurfers often look for a tech that’s crisp and exciting to ride, yet super tough and affordable. That is why we created StarLite Technology, making it an ideal choice that mixes perfectly performance, the durability of a tank and affordability all in one.

The Starlite Windsurf board Construction Details

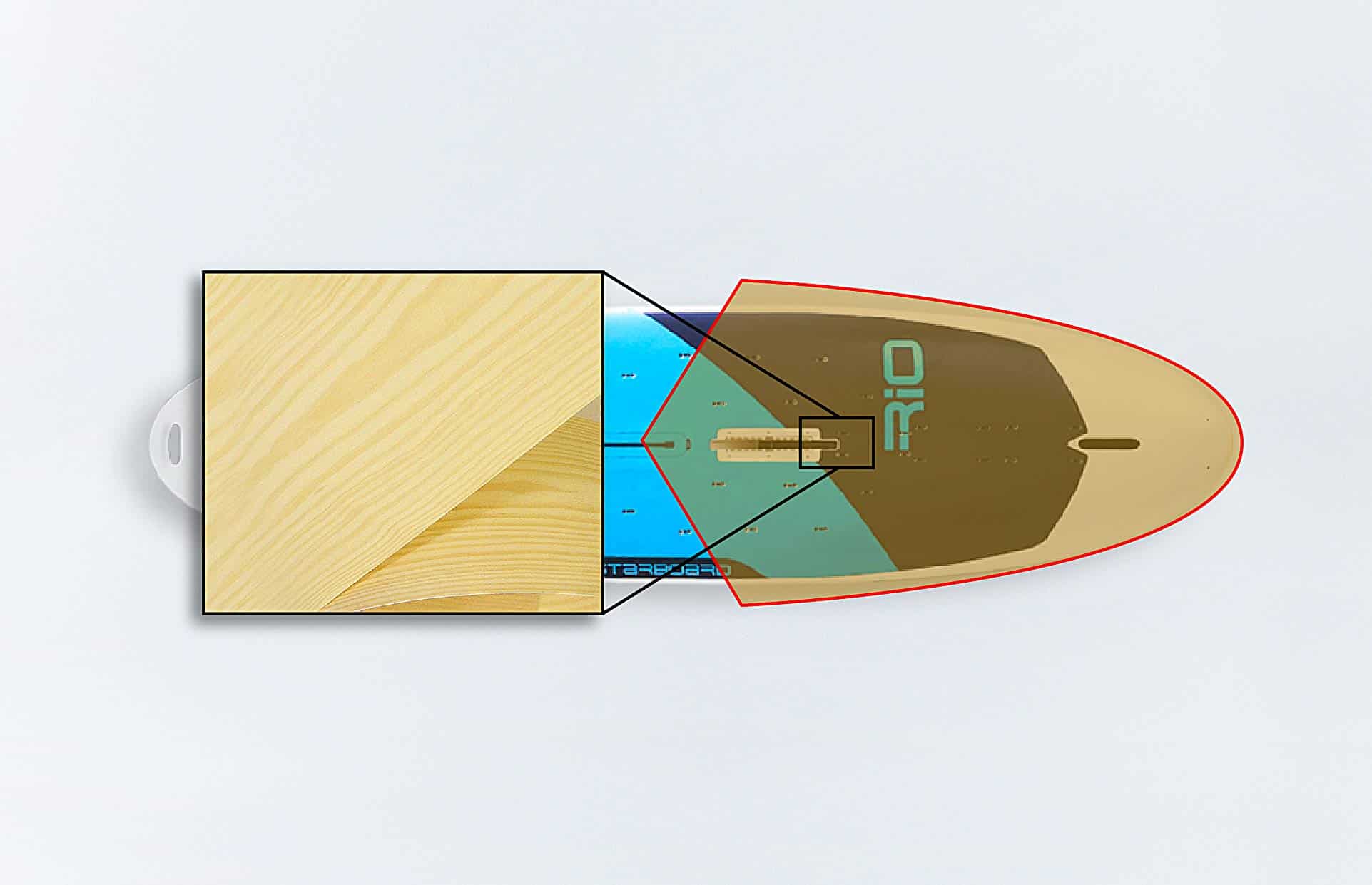

Australian Pine Wood Spine 0.6mm

Along the bottom of the board, ahead of the fin box, this section of the skin is stretched, compressed and twisted while the board travels at speed over chop. Because Australian pine is uni-directional, rigid and 0.6mm thick, it is the ideal material to help maintain a rigid hull shape.

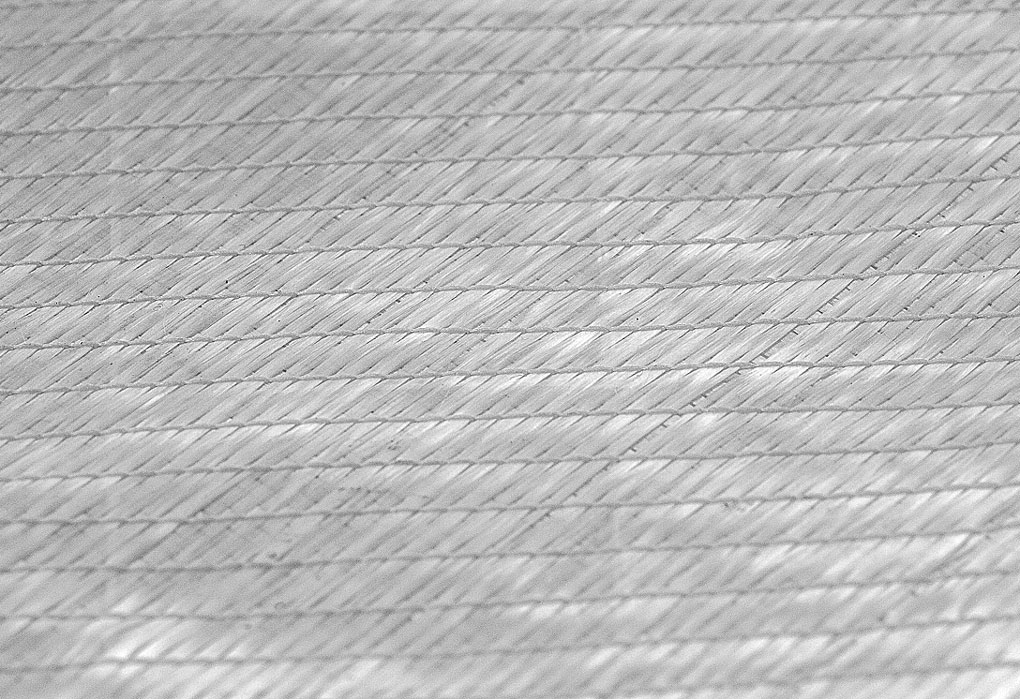

45 Degree Continuous Fibers

Starboard’s Starlite differentiates itself from the market segment’s stock construction by using continuous biaxial glass fibres instead of chopped, multi-directional short strand glass fibres. Each fibre works continuously along its uninterrupted length to provide stiffness. It’s like comparing spaghetti to macaroni: straight spaghetti strands are more effective at making a board stiff. Orientated at 45 degrees, Starlite boards are stiff but still flex and reflex: for performance with comfort.

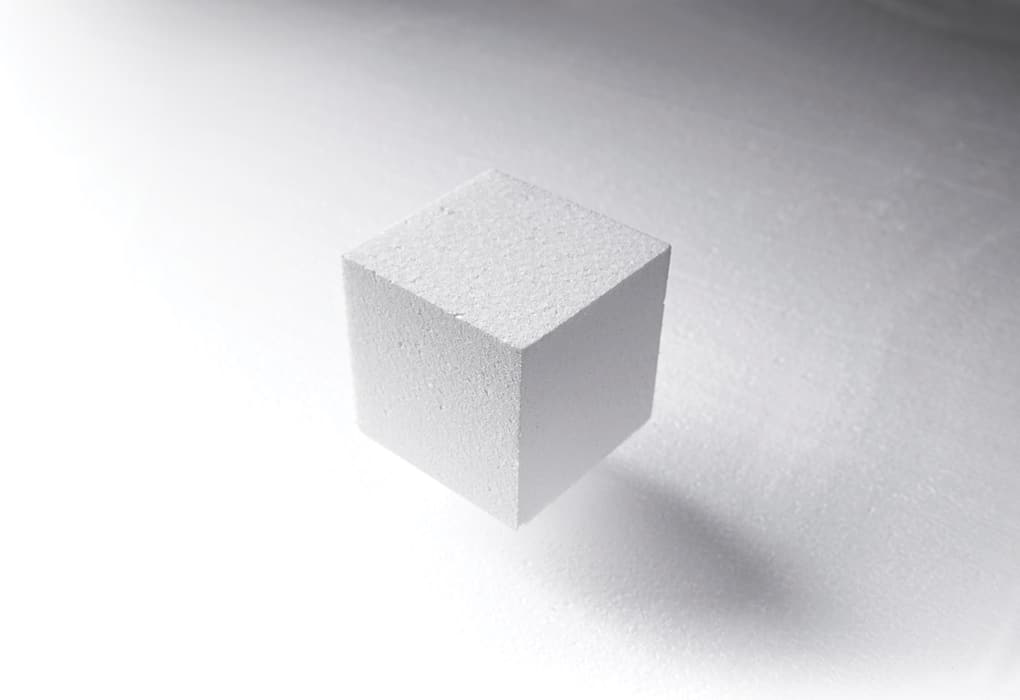

EPS Core – 15.5kg/m³

Shear resistant, fused and moulded individually to fit each and every Starboard board providing high strength at the lightest weight. Our moulded core technology produces zero EPS wastage.