Wood Sandwich

Construction Technology

LIGHTWEIGHT BOARDS DESIGNED FROM THE GROUND UP AS OUR LOWEST CARBON FOOTPRINT

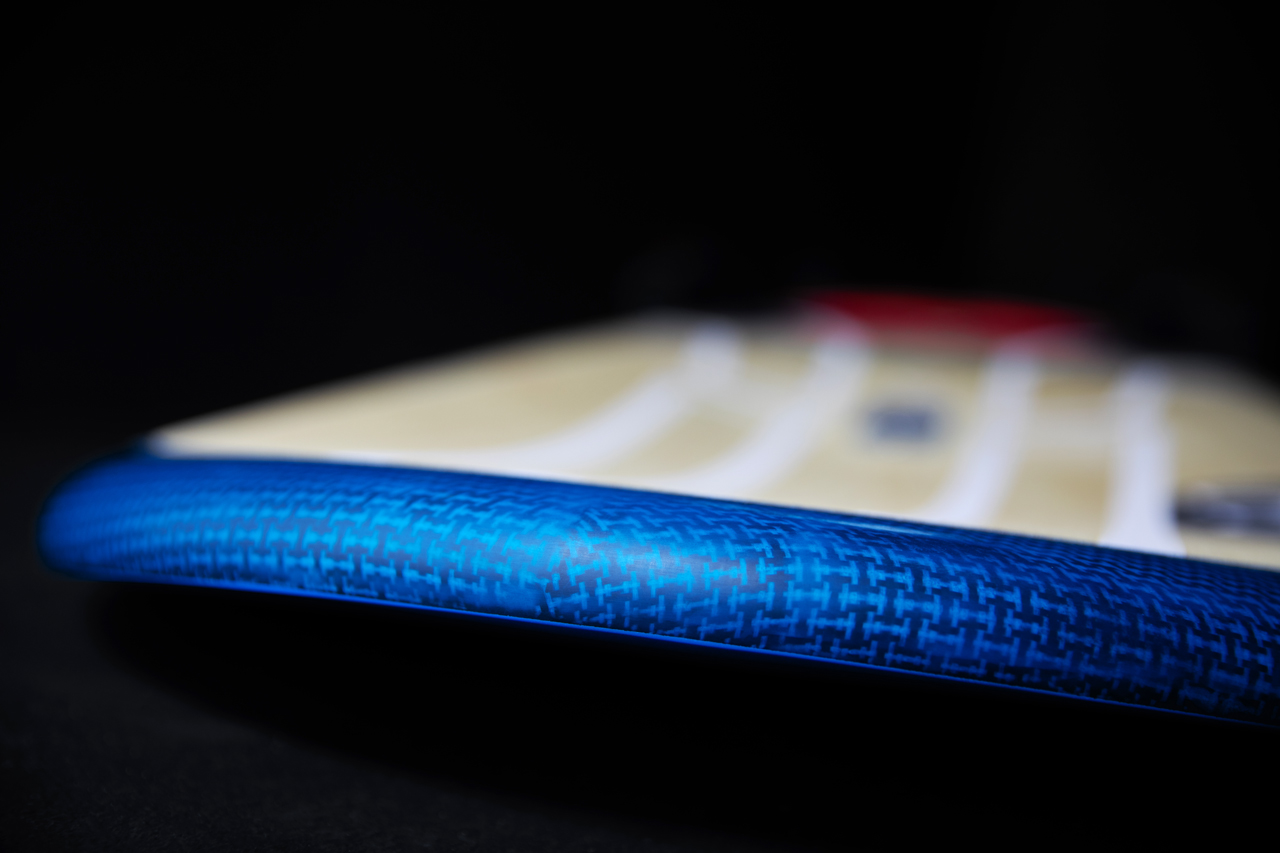

Developed by Jean Louis Colmas in 1984, Wood Technology became Starboard’s trademark construction in 1995. Wood Technology remains a favorite for riders preferring more comfort, more control and the unique crisp feel of an original Starboard. It’s time to bring back this technology while reducing our CO2 footprint. Full wood sandwich lamination of 0.6mm Australian Pinewood, ensures durability and comfort in a good strength-to-weight ratio. Today’s wood is more visible in modern graphics; UV protected by digital print PVC stickers that compliment the natural grain with a really nice effect. A classy re-edition of a classic Starboard Original.

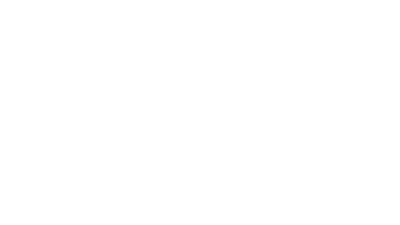

WOOD SANDWICH CONSTRUCTION DETAILS

DESIGNED. FROM THE GROUND UP

Durable lightweight technology designed from the ground up as our lowest carbon-footprint boards. Using high strength Sicomin epoxy resins, optimally positioned and carefully aligned panels of natural 0.6mm Australian Pinewood, providing full deck sandwich construction with optimal fatigue properties, excellent shear strain, overall stiffness and reduced weight.

NATURE'S WONDER MATERIAL

Wood Technology, introduced by Starboard back in 1995, weighed a kilo less than the best boards at the time. Today, we bring back this classic technology utilising the low resin absorption and naturally unidirectional benefits of Australian Pinewood, improved impact resistance and lower laminate weights. Crisp and responsive on the water, yet smooth, comfortable & durable.

FLEX OPTIMIZATION

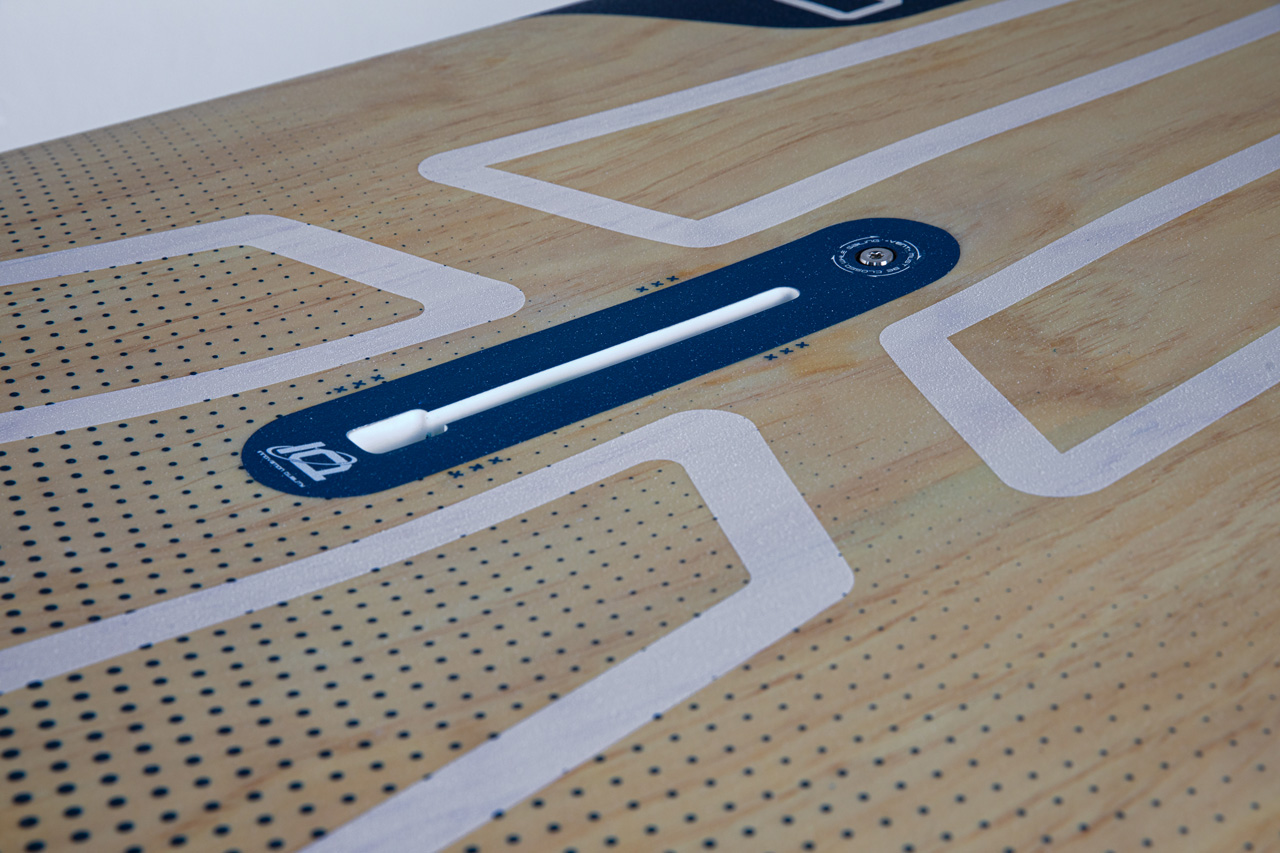

We’ve added extra-light unidirectional carbon strips along the Kode rails to further stiffen the board between the back foot and the mast track plus Innegra Carbon rails all around the iSonics & Futuras for extra stiffness and impact resistance.

FUSED EPS CORE – 15.5 KG/M³ DENSITY

Shear resistant, fused and moulded individually to fit each and every Starboard model to minimize waste. Better for you. Better for the environment.